Have it your way

Make a difference with IMD Sustainable business Programs 🌳

You know that sustainability is an imperative for your business. The real challenge is knowing how to transition from commitment to action, to successfully navigate the complexity of your sustainability transformation.

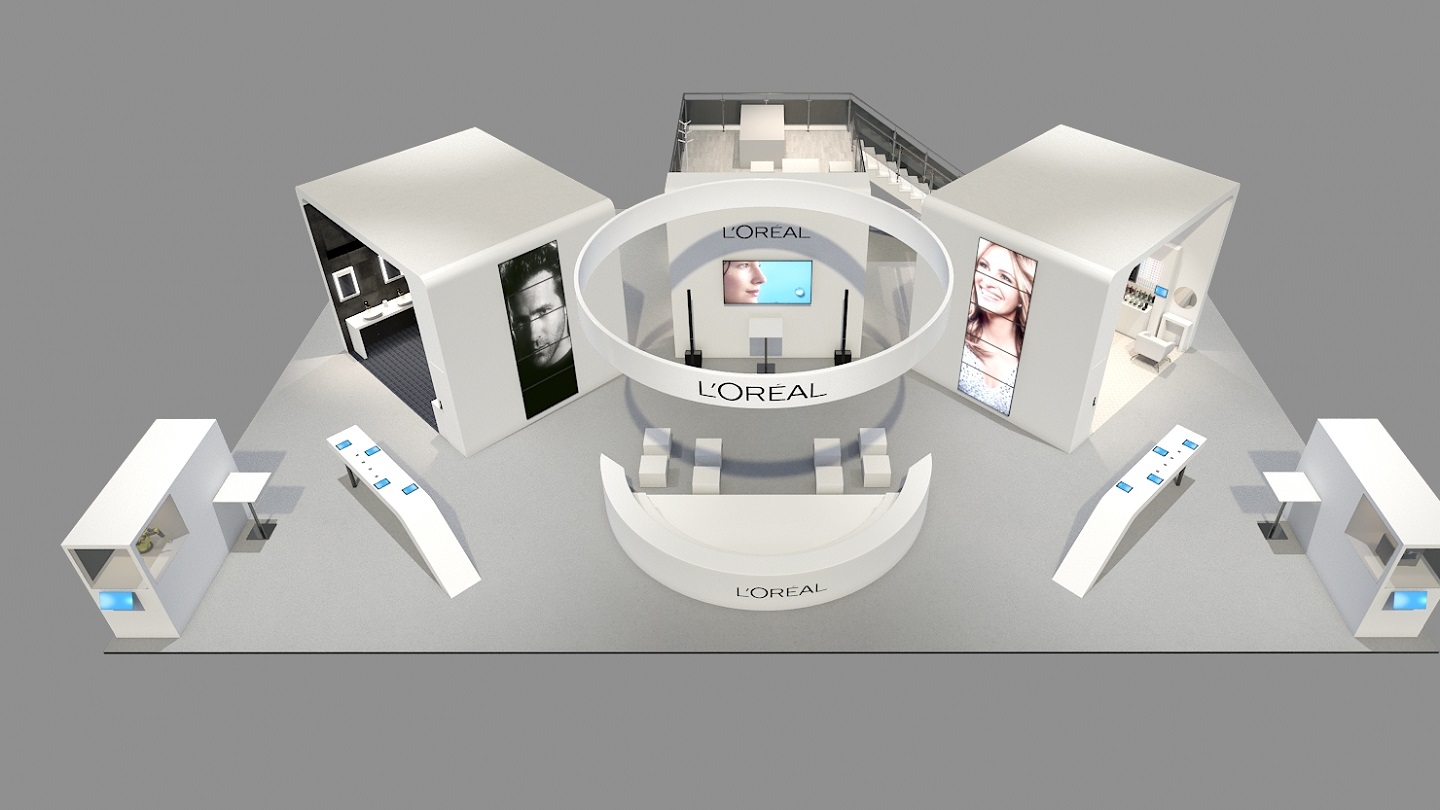

Personalization starts with the customer

We spoke to Amir Andskog, e-Commerce Supply Chain Director at L’Oréal Luxe, to understand the challenges of initiatives like My Little Factory. He started by pointing out the need to rethink data management structures and then to consider reactivity.“We certainly can’t create 22,000 new product codes and work as we did in the past. New, imaginative ways of tracking and storing products will be needed, ones that can manage master data in a much more flexible and adaptable way than today. The customer will expect lead times approaching those of the current standard products. Our factories must rethink their manufacturing processes in order to produce and ship within one day.” Amir Andskog, e-Commerce Supply Chain Director at L’Oréal Luxe

Challenging the manufacturing mindset

Increased customer proximity in the factory may also push for changes of other engrained mindsets. Manufacturing in many companies has undergone years of consolidation and massification. Fewer production centers and larger batches drove economies of scale in order to lower cost of goods. This approach extended to the sourcing of materials as well, all with an emphasis on removing production inefficiencies. The result is often global manufacturing footprints, with large productions runs. For personalization to succeed at scale, this model must evolve. Most obviously, personalization means a run size of one. But with the customer proximity and lead time expectations of personalization global footprints may become more local again, or at the very least, regional.“Personalization will oblige the organization to be mature enough to look at the total cost of the product including obsolescence, not just the manufacturing or sourcing cost. This new model will encourage shared profit and loss statements (P&Ls) across functions.” Eric Lefranc, an experienced operations expert with three different luxury companiesEric echoed Amir’s thoughts about the challenge of customer proximity to manufacturing. “The data management and reactivity requirements will foster semi-automatic processes combined with empowered staff at the shop floor level that are highly motivated to be closer to the consumer.”

A boost for lean

Small runs, customer driven manufacturing and empowered staff are all hallmarks of Lean Manufacturing.“Lean is a dynamic system that frames and stimulates the activities of employees aiming at flow improvement and people development. It enables employees to foster and leverage organizational learning in order to always better satisfy customers.” Florian Magnani, Operations professor and o-author of ‘540° to Lean’Florian agreed that personalization could spur companies to embrace Lean in its purest sense, and indeed may be a necessary pre-requisite to success. He pointed out that even Toyota, whose production system inspired Lean, continue looking to shorten their production lines and give more responsibilities and autonomy to their staff in order to better respond to personalization.

Outlook for personalization

If Personalization is to truly succeed at scale, companies will have to rethink fundamental pillars of their manufacturing policy. It goes deeper than technology. Indeed, it’s not apparent that L’Oréal’s My Little Factory will involve any Industry 4.0 elements. Total cost of ownership, quality processes, manufacturing footprint, supplier relationships, upstream/downstream silos, IT and data management are all elements that must be rethought in addition to channel placement. The result may be that what is old becomes new, and smaller, regional factories embrace Lean as a lever for commercial success through Personalization. Ralf W. Seifert is Professor of Operations Management at IMD. He directs IMD’s new Digital Supply Chain Management program, which addresses both traditional supply chain strategy and implementation issues as well as digitalization trends and new technologies. Richard Markoff is a supply chain researcher, consultant, coach and lecturer. He has worked in supply chain for L’Oréal for 22 years, in Canada, the US and France, spanning the entire value chain from manufacturing to customer collaboration.Make a difference with IMD Sustainable business Programs 🌳

You know that sustainability is an imperative for your business. The real challenge is knowing how to transition from commitment to action, to successfully navigate the complexity of your sustainability transformation.

Research Information & Knowledge Hub for additional information on IMD publications

Executive Programs

Upcoming Events

How Maersk is rewriting the rules of shipping decarbonization – through collaboration, purpose, and placing big bets on the fuels of the future.

Stefan Noeken, former EVP of Supply Chain Management and member of the executive board at Hilti Corporation, offers insights into the strategic evolution of supply chains and the key imperatives required to drive sustainable supply chain transform...

Arcos Dorados leverages 2,400+ McDonald’s across Latin America to promote youth employment, nutrition, sustainability, and ethical sourcing at scale.

With 25 years of experience across leading multinationals like Philip Morris International (PMI), Firmenich, and Danone, Luca Nanni believes supply chain can serve as a strategic driver for business success and leadership development.

Building the Foundations for Sustainable Performance means using AI and expert insight to evolve supply chains and meet the operational demands of 2025.

As Trump-era policies return with sharper edges, companies must rethink supply chains not for speed, but for resilience.

This brief case exercise presents an increasingly common business scenario: An established player acquires a small, agile start-up to re-energize its value proposition. In this case, established global beauty giant UrbanLuxe acquires beauty start-...

The supply chain risk management literature differentiates between disruption risk that arises from supply disruptions to normal activities and recurrent risk that arises from problems in coordinating supply and demand in the absence of disruption...

The US deal granting it future revenue and access to Ukraine’s mineral sector raises a broader question: is this the beginning of a model for American foreign policy, one that links strategic resource access to long-term diplomatic and financial c...

Multinational businesses are recalibrating their global supply chains, with one eye focused firmly on Washington. As the Donald Trump administration reignites the use of tariffs as a blunt instrument of economic leverage, so-called “friendshoring”...

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

in I by IMD

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

in Production and Operations Management June 2025, vol. 34, issue 6, https://doi.org/10.1177/10591478241302735

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications

Research Information & Knowledge Hub for additional information on IMD publications